Most common risks when working with a telehandler

Even today, in 2018, accidents with telehandlers are still a frequent occurrence. Statistics show that the main cause, accounting for 20% of the accidents, is due to the loss of control over a machine, vehicle, object or animal. That is why maintaining control over the telehandler is of great importance for the safety of yourself and your environment.

WORKING SAFELY: A MATTER OF KNOWING, BEING ABLE TO AND WANTING

The employee must have sufficient knowledge of the safety regulations in order to be able to get started. Insufficient knowledge often lies at the basis of industrial accidents. To comply with this, it is important that all users receive a professional telehandler trainer. Furthermore, the law prescribes that employers must take to protect the safety and health of their personnel and, as a result, provide a suitable training course.

The environment and the conditions must allow the employee to work safely. The employer must make sure that the telehandler has a CE-certificate. Moreover, there is the Last Minute Risk Analysis – or simply the LMRA: a practical method whereby the driver of the telehandler checks whether the work area and the machine itself are safe to work with. The driver performs a risk assessment and takes any necessary measures. The telehandler is then only used when the situation is safe for people, the environment and the equipment. How you perform such an inspection? Read all about it in our ‘Checklist for the maintenance of your telehandler’.

The employee also has to take the responsibility to meet the safety regulations. Each employee is obliged to take care of his own safety and that of others, yet it still happens that e.g. other persons are transported on the telehandler, or that the capacity range is not observed.

WHAT IS THE LIFTING CAPACITY OF A TELEHANDLER?

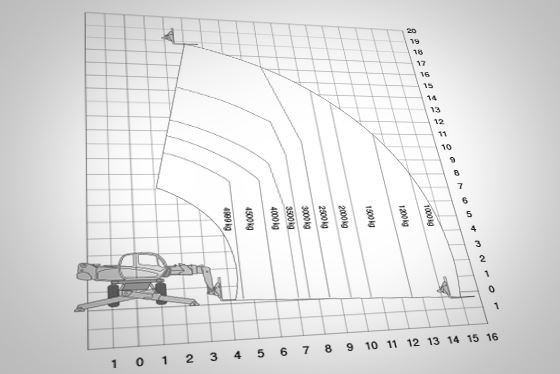

The lifting capacity of a telehandler or the maximum permitted weight of the load is calculated in function of the distance from the load centre compared to the fork heel. This information is displayed in a load diagram.

Thanks to the hydraulically extending telescopic arm – or simply the boom – the lifting capacity of the telehandler is increased. The boom runs along the cabin and is mounted on the back of the telehandler. As a result, nearly the full weight of the machine is used as a counterweight. The capacity of a telehandler is proportional to the stability.

HOW (UN)STABLE IS A TELEHANDLER?

A telehandler has no suspension, causing it to be more prone to tipping. The stability of a telehandler depends on three important elements:

- Dynamics of the centre of gravity of the telehandler and the load

- Inertia

- Centrifugal force

The centre of gravity of the telehandler is the point with respect to which the mass of the telehandler is in balance. The centre of gravity is always the centre of the weight, but this depends on the distribution of the weight. That is why the centre of gravity of a telehandler is not always the centre of the telehandler, but of the load it is lifting.

Inertia can occur when a heavily loaded telehandler brakes or reverses abruptly. In other words, there is a force that opposes the acceleration or the deceleration. Inertia depends on the magnitude of the acceleration or deceleration, and the mass. When this occurs, the telehandler can loose its load, or even tip over in the worst case.

Centrifugal force occurs when cornering. It pulls objects to the outside of the corner, as a result of which the telehandler can loose its load or tip over laterally.

The following factors can also cause the telehandler to tip over:

- collisions with other elements in the vicinity

- the influence of wind, especially if the load catches a lot of wind

- faulty stabilisers

- driving on or off a transport vehicle

- differences in height on the route followed

- insufficient horizontal work space

- insufficiently stable underground

- holes in the ground

- excessively steep slopes

- flat tyre

- overload

- 180° rotations

- sudden or jerky movements

- ...

Prevention is still better than cure, that is why we recommend to also definitely read our ‘Tips to safely work with e telehandler’.

Ingeborg, TVH blogger