Rubber versus steel tracks, which one to pick?

When equipping a mini-excavator with tracks, there is always a question to consider: Are rubber tracks the way to go, or are steel tracks preferable? The short answer is that it depends. Both rubber and steel tracks have their own advantages and disadvantages, and which one is preferable depends on the specific working environment. In this blog, we will look at the main differences between rubber and steel tracks, their pros and cons, and the situations in which they are best used.

Versatility first with rubber tracks

Mini-excavators with rubber tracks can shine in environments where they mainly encounter difficult surfaces, such as construction sites or agricultural fields.

Pros

- Surface protection: Due to their composition, rubber tracks are gentler on surfaces and leave hardly any marks. This makes them suitable for urban environments, landscaping and work on delicate surfaces that require a degree of protection.

- Lower ground pressure: Rubber tracks distribute the machine’s weight more evenly, reducing the risk of sinking on softer terrains.

- Operator comfort: The flexibility of rubber tracks allows for a smooth ride with less vibration, which makes the working day more comfortable for the operator. Of course, it’s important to note that the job’s smoothness also depends on the circumstances on the site.

- Quiet: Mini-excavators with rubber tracks produce less noise than other track types, useful in urban settings or noise-sensitive environments.

- Maintenance: Routine maintenance is still required, but it's usually less intensive than steel tracks.

Cons

- Durability: Although durable, rubber tracks can wear out faster than steel tracks in highly abrasive conditions. They are also more susceptible to damage or tearing when driven over sharp objects or uneven ground.

- Traction: Rubber tracks provide less traction on very rough terrain. They are also more challenging to drive on wet or muddy surfaces.

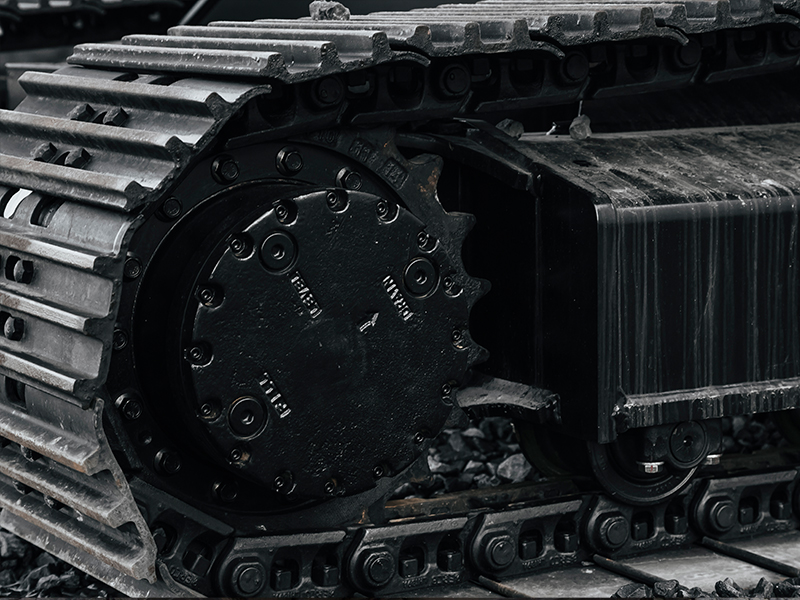

The sturdy durability of steel tracks

Because of their sturdiness, mini-excavators with steel tracks perform better on soft and uneven terrain.

Pros

- Durability: Steel tracks are highly durable and sturdy. They can withstand the harshest working conditions and are less likely to get damaged by sharp objects or debris. This makes them an ideal choice for heavy-duty applications.

- Longevity: When properly maintained, steel tracks generally have a longer lifespan than rubber tracks, especially when used in harsh environments.

- Stability: Because of their solid base, steel tracks offer more stability. This reduces the risk of the mini-excavator getting stuck or losing balance in muddy or uneven terrain.

- Traction: Mini-excavators with steel tracks offer excellent traction, making them suitable for challenging surfaces such as rocky terrain or steep, muddy slopes.

Cons

- Surface impact: Compared to rubber tracks, steel tracks are harsher on sensitive surfaces like asphalt or lawns. They can even cause damage and are, therefore, not suitable for projects where protecting the surface is an important consideration.

- Higher maintenance: Steel tracks require more regular maintenance, including lubrication and tension adjustment, to ensure their longevity and performance.

- Operator comfort: Because of the rigid nature of steel tracks, operators may experience more vibration and jolts during their working day.

- Noisy: Steel tracks generate more noise on hard surfaces, which can be an issue in residential areas or noise-sensitive environments.

Rubber versus steel, when to pick which?

In short, the choice between rubber and steel tracks for mini-excavators often depends on the complexities of the project, including the terrain and the nature of the machine's tasks. Rubber tracks provide a smooth ride and protect surfaces but can wear faster in extreme conditions. On the other hand, steel tracks excel in rough terrain but at the expense of surface-friendliness and operator comfort.

Can you convert steel tracks to rubber?

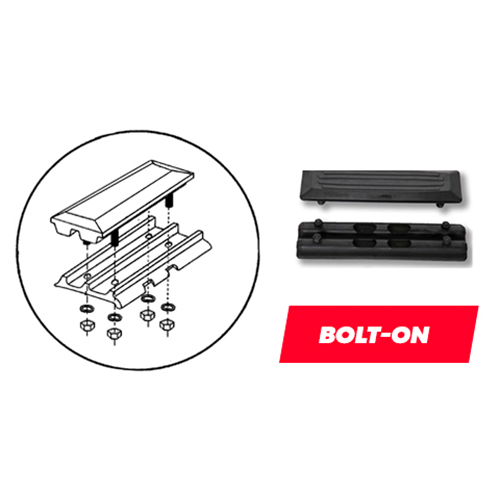

For those who want to retain the benefits of steel tracks while gaining versatility and ground protection, there is a compromise: rubber pads! Essentially, rubber pads are track shoe covers made from durable rubber. Mounting them on the steel tracks of mini-excavators is a straightforward process, with several options available:

Bolt-on

The rubber pads are mounted directly onto the steel track. This solution is durable and cost-effective.

Chain-on

With this setup, the steel plates must be removed before the pads can be fitted. An important advantage is that the rubber surrounds the steel part of the track, minimising the risk of damage to the surface.

Clip-on

The rubber pads are slid sideways onto the steel plates and secured with brackets (clips). This type contains more rubber and is heavier, which minimises wear and makes it more durable.

Looking for tracks for mini-excavators?

When it’s time to replace mini-excavator tracks, technical support will come in handy. Finding the right replacement parts isn’t always easy: there are no international norms or standards for the measurement of tracks, and every make has its own system for undercarriage parts.

Therefore, the best way to find the right tracks and undercarriage parts is through the machine details (make, model, etc.):

- Go to the MyPartsFinder search function in our online shop.

- Enter the machine details.

- Find the parts you need!

Not 100% sure what part(s) you need to order? Don’t worry, you can always contact us! Our skilled colleagues are ready to give extra support.

You may also be interested in the following blogs:

About the authors

This blog post is brought to you by your construction equipment marketing team.

Request your customer account to shop parts online

Submit the application form to specify your business needs and request your customer account.

Our sales team will contact you within 3 business days to talk about your business needs and complete registration.

After your account is set up, you will receive a personal login to our online shop. We will guide you in finding parts and placing your first order.

Request your account

Over 75.000 customers trust TVH as their spare parts supplier to ensure their client’s equipment fleet is running smoothly and efficiently. It starts with a customer account.