16 September 2022

A tractor is a valuable investment. Whether you use it occasionally or on a daily basis, you need it to be in good condition and ready to work. This means keeping it well maintained.

Most farmers give their tractors an inspection and tune-up at the end of the harvesting season, ensuring the machines are good to go for the next year. But this isn’t the only time you should check a tractor. With heavy machinery, safety is the number-one priority. Maintenance is essential for optimising not only the performance, but also the safety of the tractor. That’s why we recommend carrying out inspections on a regular basis, and maintenance as soon as you spot an issue. This way, you’re able to prevent small problems from growing into giant expenses, or worse yet, tragic accidents.

You can carry out a general inspection of a tractor at any time. If it’s used almost every day of the week, you’ll want to inspect it regularly, perhaps once a fortnight or even once a week. If the tractor only comes out on rare occasions, it’s a good idea to inspect it before every use, just to make sure nothing has become damaged or degraded since it was parked in the shed.

Not sure what to do? Read on to discover how to check a tractor for damage and functional issues and keep it running smoothly for longer. Bear in mind, these are general guidelines. For instructions for a specific machine, check the tractor’s manual.

Begin with a general inspection

Maintenance starts with observation. Take a really good look at the tractor, keeping an eye out for any obvious damage, wear and tear, leaks, and any other visible problems. Make sure you do a full walk-around and check all parts of the machine. Then examine the engine, looking for anything out of the ordinary like pipes that have been disconnected or parts that are worn out.

Clean the tractor regularly

Dirt, dust and grime can cause havoc if they get into moving parts. Thankfully, you can stop them in their tracks by cleaning the tractor. Use steam or compressed air to clean dirty parts and the recommended degreasers to remove oily build-up. Once you’re done, take a minute to ensure all the tractor’s safety symbols and decals are still visible.

Check the tyre pressure

It’s such a simple thing. But you’d be surprised how many farmers suffer low performance and safety issues from using tractors with under- or over-inflated tyres. Tractor tyres should be kept at the recommended pressure. If you don’t know what that pressure is, find it in the technical information sheet for the tyres or ask your dealer.

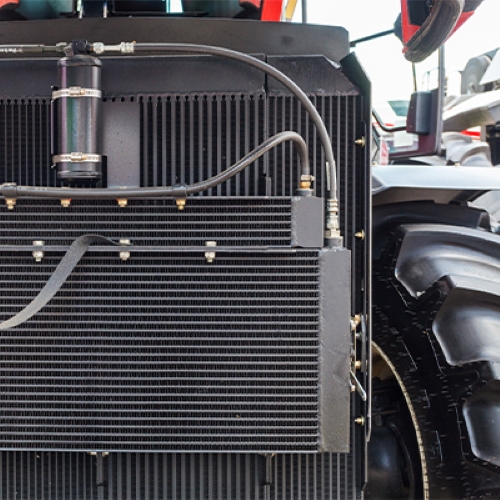

Make sure the engine-cooling system is working properly

A tractor’s engine-cooling system is critical. The part that’s most likely to wear out is the cooling belt. Thankfully, it’s pretty easy to replace when it does. But to do that, you need to know when you’re heading into problem territory. That’s why the tension of the cooling belt should be checked regularly.

It's also important to make sure there’s enough coolant in the system. Whenever it’s low, it needs to be topped up right away. Check that the tractor has the proper level of coolant before heading out into the field or you might end up with an overheated engine, which can cause irreparable damage if not addressed quickly enough.

Be sure the battery is in good shape

Without a working battery, a tractor won’t be ploughing any fields. You can’t even start the machine without it. Depending on the type of battery, the battery fluid might need to be topped up frequently. If you don’t know how to check the fluid level, or how to top it up, consult the manufacturer.

No matter what type of battery a tractor has, it should be replaced every 3–5 years, depending on how often the machine is used. If the battery is more than five years old, it’s almost certainly time to arrange a replacement.

Check and replace the filters

A tractor’s engine contains a variety of filters that keep contaminants out of the system. These need to be checked regularly and replaced when they become too worn out to function properly. Check the following filters whenever you do an inspection:

- Air filter – Stops dust and debris from getting into the engine. It needs to be cleaned regularly, especially during the dusty seasons.

- Fuel filter – Keeps contaminants out of the fuel system. Metal fuel filters can be cleaned and reused, but nylon and paper filters should be replaced once they get grimy.

- Oil filter – Removes dirt, sludge and debris from the engine’s oil supply. It should be cleaned every time the oil is changed.

- Transmission filter – Stops contaminants hitching a ride in the transmission fluid and obstructing smooth and efficient operation of the transmission.

- Hydraulic filter – Ensures hydraulic fluid doesn’t get clogged up with gunk, which can slow down the system and damage the tractor.

Inspect the oil levels

Things are going to get clunky and dangerous if a tractor runs out of oil. That’s why the oil levels need to be checked regularly and topped up whenever necessary. Transmission, engine and differential oil should be changed every 250 working hours.

Check the lubrication points

Lubrication points are places where oil is applied to enable moving parts like bearings, gears and sprockets to work smoothly. If these points aren’t properly lubricated, the tractor is likely to break down, which is never convenient. Proper lubrication also helps to extend the lifespan of vital engine parts like belts and chains.

When checking lubrication points, look for signs of wear or damage like cracks or corrosion near where the oil is applied. If you discover any, those parts might need to be replaced immediately or in the near future. It’s also a good idea to check the tractor’s nuts and bolts when checking the lubrication points. Make sure they’re tight and unlikely to come loose while the tractor is in use.

Examine the exhaust system

A tractor’s exhaust system includes the muffler, exhaust pipes and catalytic converter. How often these need to be inspected and maintained depends on how old the tractor is, what type of engine it has, and how many hours it’s been used for. Consult the manual for the manufacturer’s recommendations.

Some tractors also have a diesel particulate filter (DPF) that removes contaminants from the exhaust system. For most tractor engines with DPFs, you should also check the AdBlue level whenever topping up the diesel.

Have a look at the hydraulic system

A tractor can’t function smoothly if the hydraulic system is out of whack, so it needs to be inspected regularly. Make sure the hydraulic pump and its fittings are working perfectly, clean the hydraulic oil and replace it when required, check and clean the hydraulic filter, and inspect the seals and hoses, replacing them as necessary.

Service the air-conditioning system

Checking the air-conditioning system in a tractor is super important because leaks aren’t just a problem for the tractor, they’re a hazard for humans. Keep operators safe by ensuring the air-conditioning system is serviced at least once a year.

Now that you know what to look out for, keeping tractors in top condition will be a piece of cake. For details specific to a machine, get in touch with the manufacturer.

Looking for spare parts and tools? Contact us. With everything you need for maintaining and servicing tractors, TVH keeps you going.