Your essential guide into the world of forklift masts

Once you start wading into the world of masts, it’s easy to get bombarded with complex terms and abbreviations. Triplex? Free View? Trust us, it’s not that complicated. Let’s have a closer look at these lifting superpowers, so you’ll be able to select and maintain yours with confidence.

Masts are used with forklifts, pallet stackers and many other machines. It is the part of your machine that allows you to lift or lower loads. In many cases, masts come with extra functionalities like tilt and side-shift. The tilt function adjusts the angle of the forks, preventing the load from slipping off. The side-shift enables the horizontal, sideways movement of the forks, to place and pick loads more precisely. These features are powered by the hydraulic circuit of your machine.

Clarifying the jargon

Masts can generally be divided into four types. Based on the number of sections or stages in the mast, you can find standard, two-stage, three-stage and four-stage masts. Before we dive deeper into these different types, it’s important to understand a few basic terms first.

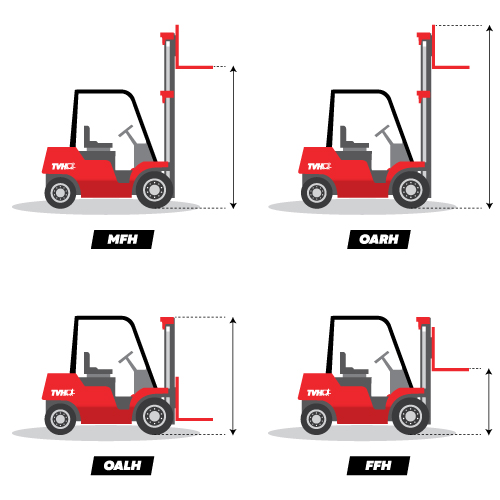

The Maximum Fork Height (MFH) is the maximum height your forks will reach when all the sections of the mast are fully extended.

The Overall Raised Height (OARH) and Overall Lowered Height (OALH) indicate the height of the top of the mast when the mast is either fully extended or fully collapsed.

Free Lift (FL) or Full Free Lift (FFL) is the ability to lift loads to a certain height without extending the collapsed mast sections. This is achieved by a single upright primary cylinder, also called the free-lift cylinder. The height that can be reached in free-lift is called the Free Fork Height (FFH). Free-lift masts usually have a smaller overall lowered height compared to standard ones. This is particularly important when operating in confined spaces, such as areas with restricted overhead clearance.

A container mast on the other hand is specifically designed to operate in confined spaces such as shipping containers. It’s especially useful in situations where height restrictions might otherwise prevent a standard forklift from operating efficiently.

- A Free View mast is a free-lift mast with two free-lift cylinders on the side instead of a single central cylinder. In regular free-lift situations, the free-lift cylinder is fitted vertically, halfway between the left and right sections. This can obstruct your view when handling loads. By using two cylinders on the side instead, the front view is clear and gives better visibility.

Mast types

We identify four different types of masts, easily recognised by the number of sections or stages represented.

Simplex masts (mono) are single-stage masts used with pallet lifters and stackers. They have a limited free lift and are used for lower lift heights.

Standard masts are basic two-stage assemblies. They are perfect for transporting loads outdoors or around large warehouses.

Duplex masts (two-stage) are similar to standard double-stacked masts but come with an additional free-lift feature. This decreases their overall lowered height, allowing them to operate in confined spaces, such as containers.

- Triplex masts (three-stage) and Quad masts (four-stage) operate in the same way as two-stage masts but extend to an additional third or fourth lifting stage. This increases their overall raised height and allows you to pick or place loads in higher areas. These masts typically come with free-lift features, making them a perfect match for high-stacking warehouses.

How to choose the right mast?

There are five important factors you need to keep in mind when choosing a mast.

Lift height: Depending on the height you wish to achieve, you can choose between a two-stage, three-stage or four-stage mast

Lift capacity: How much weight do you need to lift? Keep in mind that the taller the mast, the lower the lifting capacity.

Height restrictions: When you need to stack or drive into confined spaces, free-lift will be indispensable.

Visibility: A free-view mast is recommended when full frontal visibility is a must at all times.

- Machine specifications: Not all masts are compatible with every machine. It’s essential to take into account the brand, type and serial number of your machine.

Maintenance and spare parts

When handling heavy loads, safety is at risk and you’ll want to keep your mast in pristine condition. Regular maintenance is essential. Beyond the regular visual checks, it’s important to check the following components for wear and tear:

Chains are used for operating the lifting and lowering mechanism. Regular inspection and maintenance of the chains is critical to ensure safe operations. Check out our 5 tips to easily maintain your forklift chain and also make sure you lubricate your forklift chain correctly.

Hydraulic pipes are an often overlooked yet essential part of your hydraulic system. Daily usage and environmental factors can cause deterioration and damage. This could have catastrophic consequences. Inspect the pipes regularly using a strong light source to detect potential cracks, peeling, damage and leaks. Frequent preventive replacement is also advised to ensure optimal performance.

Mast rollers are the bearings between the large mast sections. Like any type of bearing, they need to be checked regularly. If the mast roller bearings are damaged, blocked or dislocated, they need to be replaced.

- Many mast types have cylinders fitted for different functionalities like the free-lift function or the side shift. Inspect the cylinder head and piston shaft regularly for signs of leakage. You may notice some build-up of fluid on the outside of the cylinder. You can also use soapy water from a spray bottle to detect a leak. Replace the seal kit when necessary.

Need a mast?

Would you like to upgrade your mast, or need a replacement? TVH offers a selection of second-hand masts for different makes and models. Contact us to find out how we can help.

Want to learn more?

Request your customer account to shop parts online

Submit the application form to specify your business needs and request your customer account.

Our sales team will contact you within 3 business days to talk about your business needs and complete registration.

After your account is set up, you will receive a personal login to our online shop. We will guide you in finding parts and placing your first order.