Sustainability and circular economy

“At TVH, we highly value sustainability and environmental friendliness. We are firm believers in the circular economy and are convinced that waste should be avoided at all costs. That is why, rather than discarding malfunctioning or broken parts, we always try to remanufacture them first. Following the Cradle to Cradle concept, we keep our remanufactured parts from landfills and hence avoid producing more parts and consuming even more raw materials”, Lorenz explains. “And if we find that a part cannot be remanufactured, then we recycle it in the correct way so that its resources can be reused.”

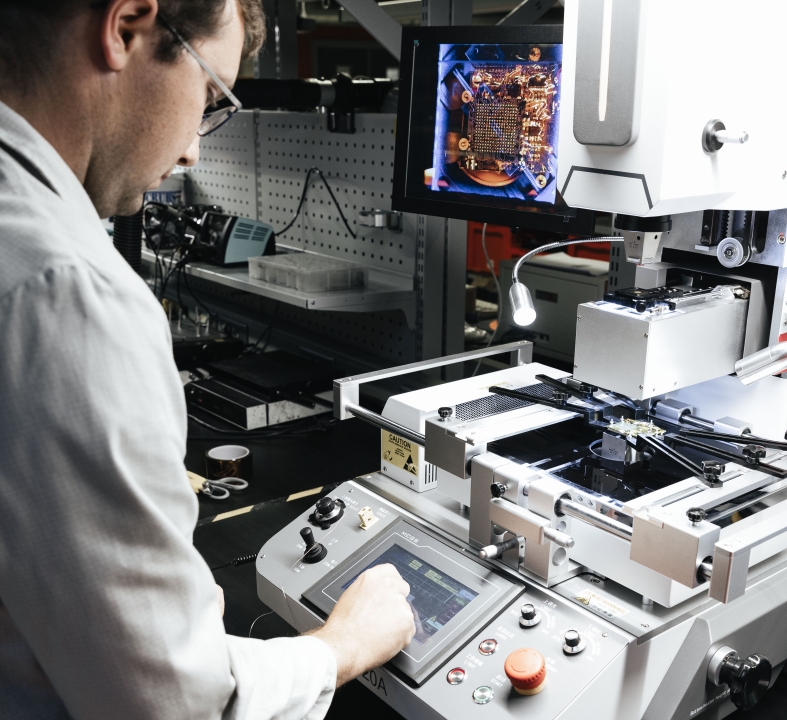

Electric System Design

“Within the Electronics Department, we also have a dedicated Electrical System Design team to support electrification projects”, Lorenz shares. “The team is specialised in providing electrical and electronic products as well as technical support during the development or upgrade of electrical applications. We are primarily aiming at small and medium-sized original equipment manufacturers who do not have the necessary resources or knowledge for that development. Using our technical expertise in the field, TVH can assist in the design of the electrical system from design to prototyping and production, Moreover, we can offer all the necessary, sometimes customised, parts.”

Rental service

"Finally, the Electronics Department also provides a Diagnostic tool rental service. If you only occasionally need a diagnostic tool, which is often quite expensive, then renting it is a good idea. Contact us, and we will check how we can help.”