Unlike a standard repair, remanufacturing involves fully disassembling the part, replacing worn and damaged components and restoring it to like-new condition. Before going to stock, the part is thoroughly tested and receives a fresh coat of paint.

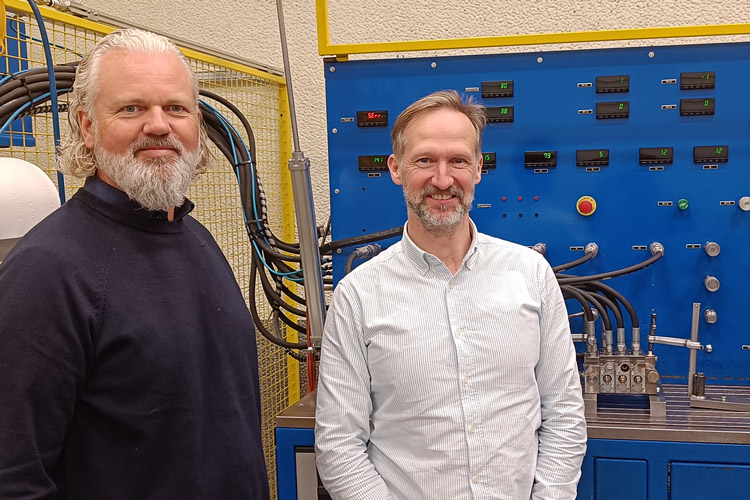

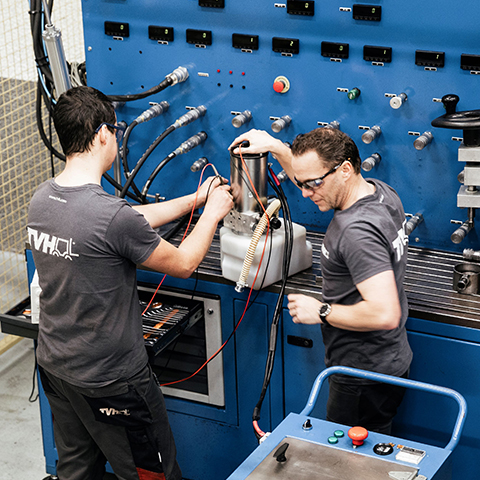

“In the past few years, we have heavily invested in new state-of-the-art test benches,” explains Joffrey. “Only the highest quality standards are good enough, and we make sure that every part that leaves the workshop works like new. We guarantee this to our customers by giving them the same 1-year warranty they get when buying new parts.”

To ensure consistent quality, the engineers always follow the same procedures.

- Initial inspection: Before dismantling any parts, they are subjected to an initial inspection.

- Dismantle: After a positive evaluation, parts are carefully disassembled for further inspection.

- Clean and repair: All components are thoroughly cleaned and inspected. Broken and worn parts are replaced.

- Reassemble: The components are reassembled to their original state following standardised procedures.

- Quality check: The parts are checked on one of TVH’s state-of-the-art test benches.

- Coat: If applicable, parts get a coat of fresh paint or varnish and end up looking like new.