Replacing the tracks on your mini excavator or skid steer loader is an expensive undertaking. Whether you are looking to buy new or used, ensuring the correct fit of the rubber tracks will give you the best value for your money. Failing to purchase the proper size will not only lead to premature track failure, but it will also place unnecessary stress on the undercarriage. When it’s time to replace your tracks, you want to make sure you’re getting the right ones for your machine. If you’re lucky, the stamp on the track with the size information will be legible. However, if it has been worn away, you’ll have to take some measurements and do some simple math to find the correct tracks for your machine.

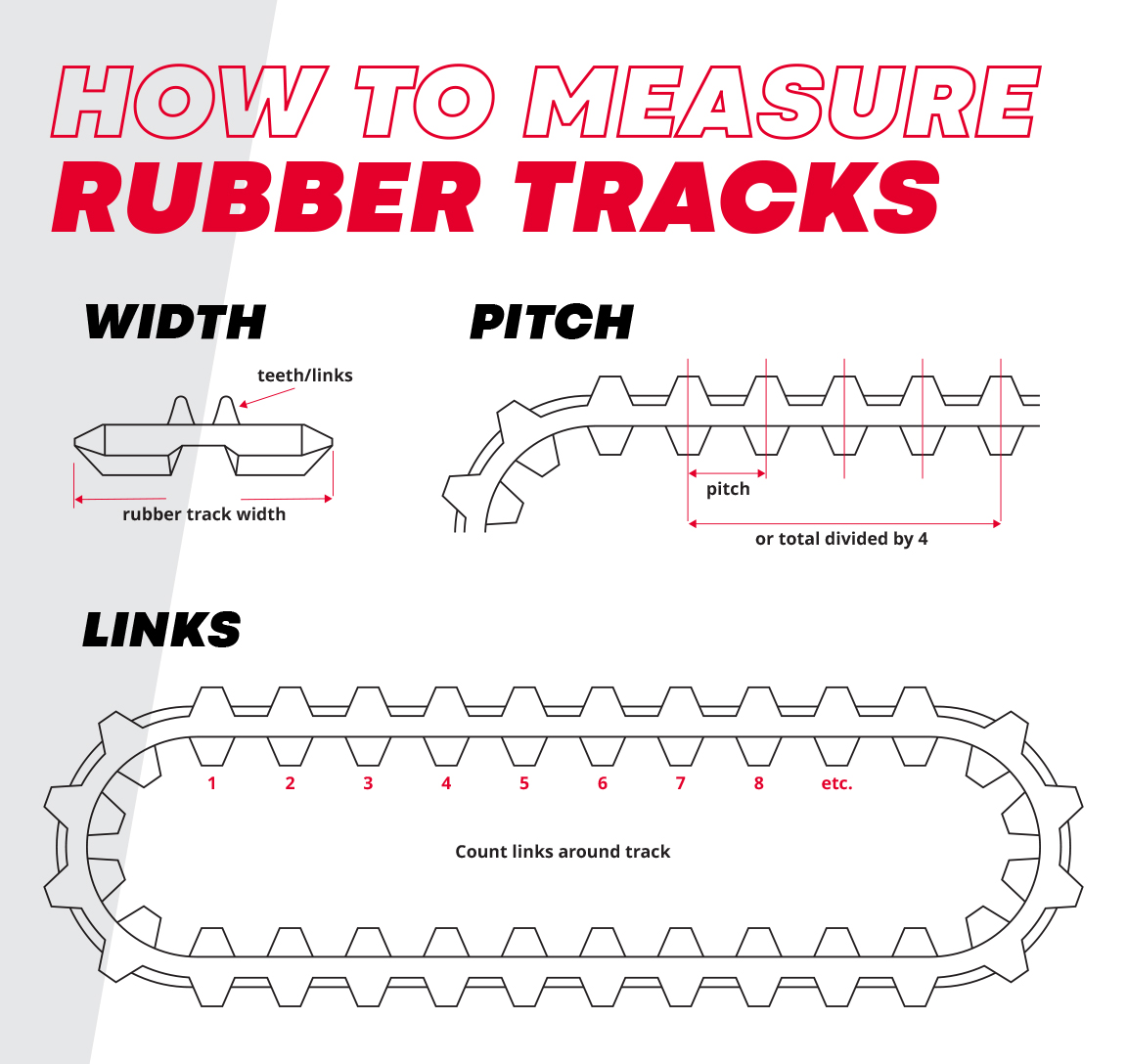

The first step is to know the make, model and year of your machine. Next, we will have to do a little measuring to find the correct size. There are three main components that we have to measure; the width, the pitch and number of links.

Measuring the Width

This is the quickest and easiest measurement to find, you simply need to measure the width of the track in millimeters. If you want to measure in inches, just remember that 1 inch = 25.4 millimeters. Or, you can always ask the internet…”Hey Siri, how many millimeters is 11.81 inches”

Finding the Pitch

The pitch is the distance between the drive lugs. You’ll need to measure this in millimeters as well. When you’re measuring the pitch, the distance should be from the center of one lug to the center of the next one. You don’t want to simply measure the open space between the two lugs as this will give you an incorrect measurement.

Counting the Links

Finally, you’ll want to count the number of links (also known as teeth or drive lugs) around the diameter of the track. These are what interlock with the sprocket and help propel the machine. You don’t want to try and guess the number of links on your track, choosing the incorrect number of links will lead to your track skipping on the sprocket.

Now that you have the dimensions of the track, it is time to put them all together. Industry standard is to present track measurements in the following formula.

Rubber Track Size = Pitch (mm) x Width (mm) x Number of Links

450mm x 86mm C x 55

You may find several tracks with the same dimensions so the next step to ensure you have the correct one is to determine your guide size and roller type. The guide system is how the bottom rollers and rear idler engage with the links. The relationship keeps the track it in place and turning smoothly. If you have an Outside Guide Bottom (OG), the rollers (known as flange rollers) run on the outside of the links. For this system, you will need to measure the distance between the outer bottoms of two links across from each other. If you have an Inside Guide Bottom (IG), the center rollers run in the space between the link pairs. For this tracks, measure the distance between the inner bottoms of two links across from each other. You will also need to measure the guide height, either on the outside of the trough (Outside Height (OH)) or from the inside of the trough (Inside Height (IH)). They guide system of a track is often indicated with a letter such as C, W, N, K, etc. There is no industry standard for the indicators and vary from manufacturer to manufacturer.

While many tracks may look alike, and even have the same width, pitch and links, it’s important that you have all of the information you need before purchasing a new pair of tracks. Choosing the wrong guide system or roller type can result in your tracks coming off the machine and even damaging the undercarriage. When it’s time to replace your tracks, think of TVH first. We offer a range of sizes to accommodate a variety of brands including Bobcat, John Deere, Kubota and Takeuchi. Even better, order a pair of tracks and receive free freight!