How does an A/C system work?

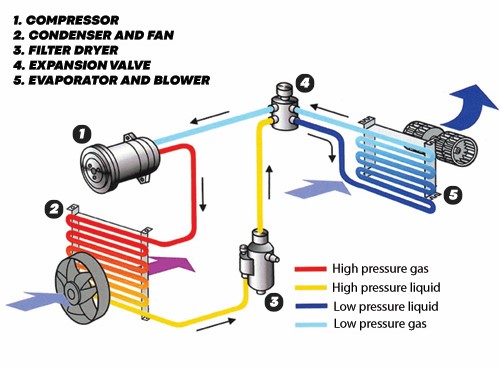

The A/C system is a closed circuit, containing a compressor, condenser, drier and an expansion valve. These are all connected through a piping system, filled with a coolant - typically R134a.

Air conditioning works by continually changing the coolant from a gas into a liquid and back. This is done by manipulating the pressure and temperature of the coolant. A compressor pushes the gaseous coolant through the system at a high pressure of around 10 - 15 bar. Subsequently, the condenser turns it into a liquid by lowering the temperature to 35 °C. Next to the condenser, the drier stops any remaining gas from entering the rest of the system. This way, the liquid can function at maximum efficiency.

The liquid flows to the expansion valve, where the pressure drops significantly to 1,2 - 2 bar and the temperature rises to 65 °C. This essentially comes down to ‘boiling’ the coolant and turning it into a gas. To accomplish this, a fan provides heat, extracting heat from its direct environment, including the cabin. The air gets cooled off and is blown back into the cabin, providing the cool air you want during hotter days.

The manipulation of the coolant is no mean feat and has its effects on the A/C system. Over time, particles break free from the different parts, polluting the coolant. This pollution can be collected by the drier, but this causes the drier to clog up, which warrants a replacement.