How the transmission and drivetrain keep a backhoe loader going

The transmission is a vital component of many vehicles and machines. Without it, the power generated by the engine wouldn’t reach the wheels in a controlled and optimised manner. The transmission’s responsibility is even more significant in small earth-movers such as backhoe loaders. Because as well as transmitting engine power to the wheels, it also ensures that this power is delivered to the hydraulic components of the loader arm and backhoe. Therefore, the transmission and all its parts must always be in perfect working order.

The role of the transmission

The transmission keeps a backhoe loader going. Literally. As a part of the machine’s drivetrain – which starts at the engine and ends at the wheels – the transmission ensures that engine power is delivered to where it’s needed in a controlled and optimised way. On the one hand, this means transmitting power to the wheels. In this role, the transmission is also responsible for speed control and ensuring smooth movement, stability and safety.

On the other hand, the transmission is also essential to the earth-moving activities of a backhoe loader. Next to driving its wheels, the transmission powers the hydraulic components of the machine’s loader arm and backhoe, allowing these components to dig, level, scoop, etc.

Manual versus automatic transmission

Most backhoe loader models have either a manual or automatic transmission. Both types are designed differently but ultimately perform the same function: to ensure that the power and torque from the engine are transferred to the wheels as efficiently as possible.

Manual transmission

This type of transmission is the most commonly known and is still widely used, although in decreasing numbers. The manual transmission gearbox consists of two axles with interconnected gear sets. Each gear set has its own ratio, which determines the final ratio of the engine RPM (revolutions per minute) transferred to the RPM of the wheels. To switch between engaged gears, the operator must press the clutch.

Automatic transmission

Because they are easy to operate, automatic transmissions are becoming increasingly popular. However, their composition makes them complicated to construct. Whereas a manual transmission is made up of several sets of gears that each have their own ratio, the ratios in an automatic transmission are produced by the same gearset: the planetary gearset. The planetary gearset is the heart of an automatic transmission, and all other transmission components support it in its job.

For example, the hydraulic valve block, which can be thought of as the brain of an automatic transmission, is responsible for the different gears/ratios of the planetary gearset. The hydraulic valve block consists of a maze of channels through which transmission fluid passes through valves. This controls the various clutches, bands and drums that change gears.

Differential

Another essential part of the drivetrain is the differential. This component is also part of the mechanism that converts engine power into torque to drive the wheels. The amount of power transmitted to the wheels depends on the traction underneath. In addition, the differential allows the wheels to spin at different speeds, which is essential for cornering. Without a differential, the wheels would constantly spin at the same speed – which they don’t normally do when cornering – and the axle would be under a lot of stress.

On a two-wheel drive backhoe loader, there’s a differential situated between the two driven wheels. A four-wheel drive backhoe loader is a bit more complicated. This type has a differential between each set of driven wheels, but there is also a differential between the front and rear wheels. This is needed because the front wheels travel a different distance through corners than the rear wheels.

But what happens when one of the driven wheels is in the air during heavy off-road work? This wheel will not get any traction, so the other driven wheel will not get enough power to move the machine. The solution to this problem is a locking differential. This mechanism can be manually activated by the operator – although automatic versions are available as well – and ensures that all power is divided equally to all wheels, even those without traction. As a result, all the wheels will spin at the same speed.

Typical replacement parts

Because its transmission is such an integral part of a backhoe loader, all parts should be in tip-top condition to ensure optimum machine performance. That is why the transmission should receive enough attention during maintenance, especially the following parts that might need replacing after a certain time:

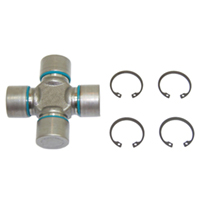

U-joint

Differential

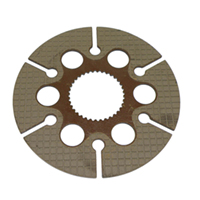

Counter plate for brake discs

Planetary gearset

In addition, the following parts can break if the machine is operated roughly:

Complete drive shaft

Differential housing

Steering axle

Steering knuckle

Handbrake calliper

Brake discs

Looking for transmission parts?

- TVH has several meaningful partnerships – for example, with Carraro – to ensure we can provide transmission parts of the highest quality.

- Go to our online shop to check out and buy our full range of transmission parts for backhoe loaders.

- Don’t hesitate to contact us if you have any questions.

About the authors

This blog post is brought to you by your construction equipment marketing team.

Request your customer account to shop parts online

Submit the application form to specify your business needs and request your customer account.

Our sales team will contact you within 3 business days to talk about your business needs and complete registration.

After your account is set up, you will receive a personal login to our online shop. We will guide you in finding parts and placing your first order.

Request your account

Over 75.000 customers trust TVH as their spare parts supplier to ensure their client’s equipment fleet is running smoothly and efficiently. It starts with a customer account.